Support

Home – Support

Case studies

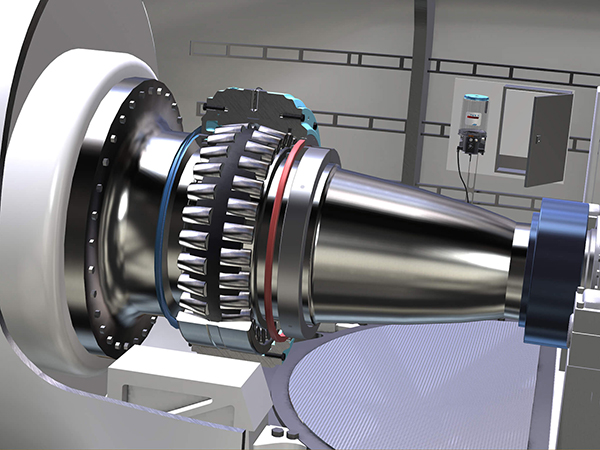

THE CHALLENGE Wind turbine planet bearings are difficult to detect early using vibration systems, but make up a majority of...

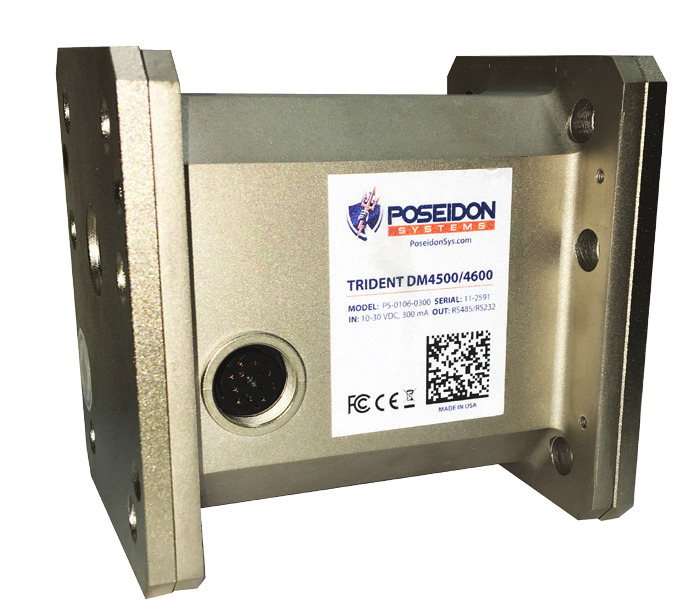

Wind Turbine Bearing Fault Detection by Trident DM4500

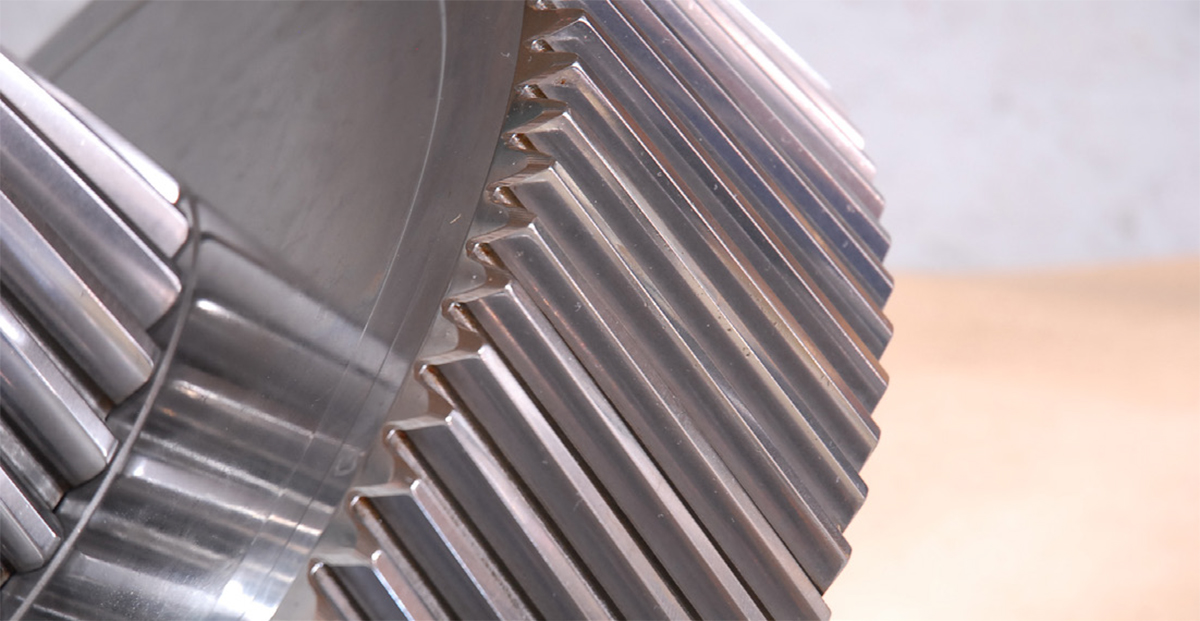

THE CHALLENGE Detecting gearbox faults prior to secondary damage; allowing for up-tower repair, significantly saving cost and extending gearbox life....

Wind Turbine Gear Tooth Fault Detection by Trident DM4500

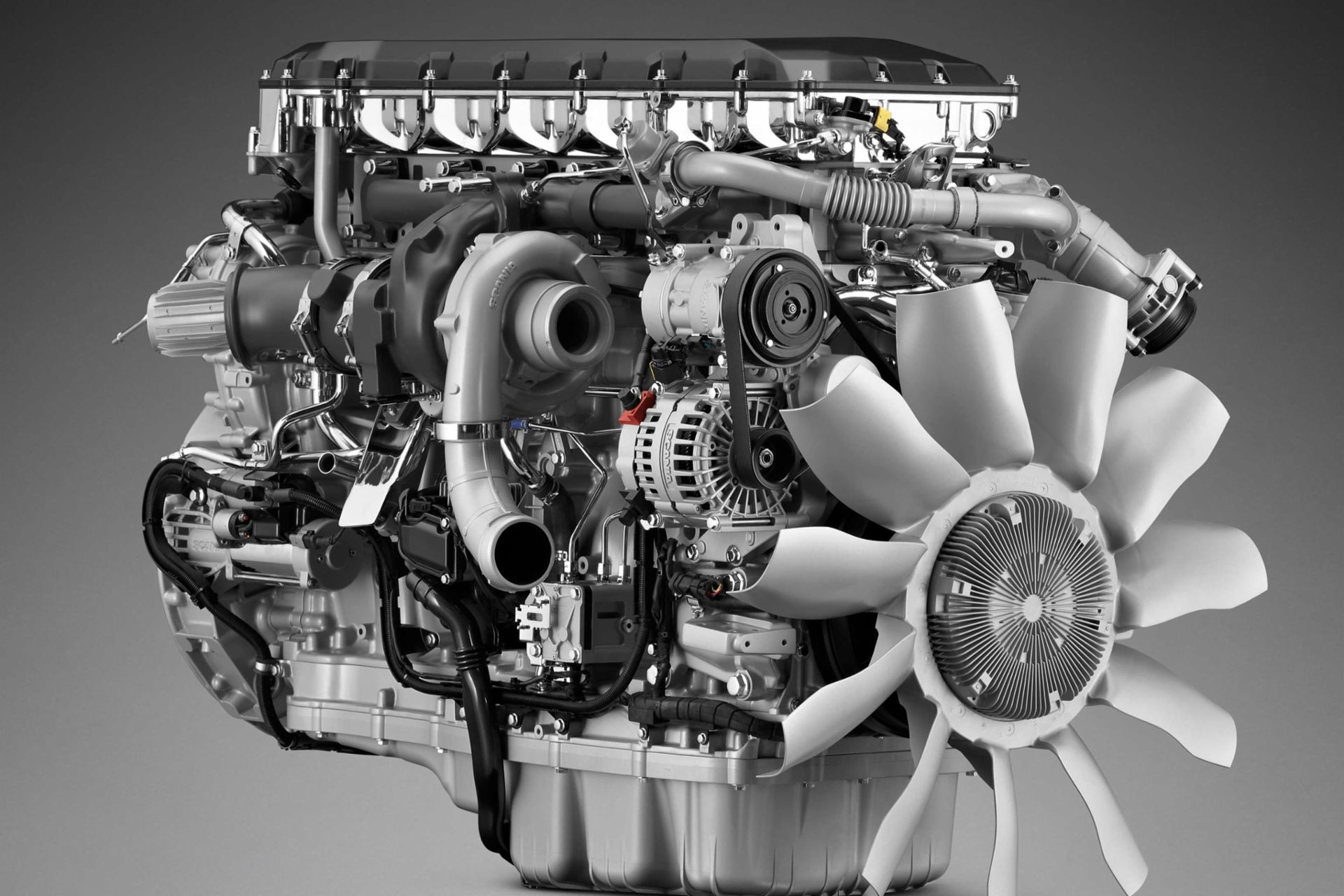

THE CHALLENGE A high percentage of coolant leaks are not detected early enough using periodic oil samples, causing secondary damage...

Diesel Engine Coolant Leak Detection by Trident QW3100

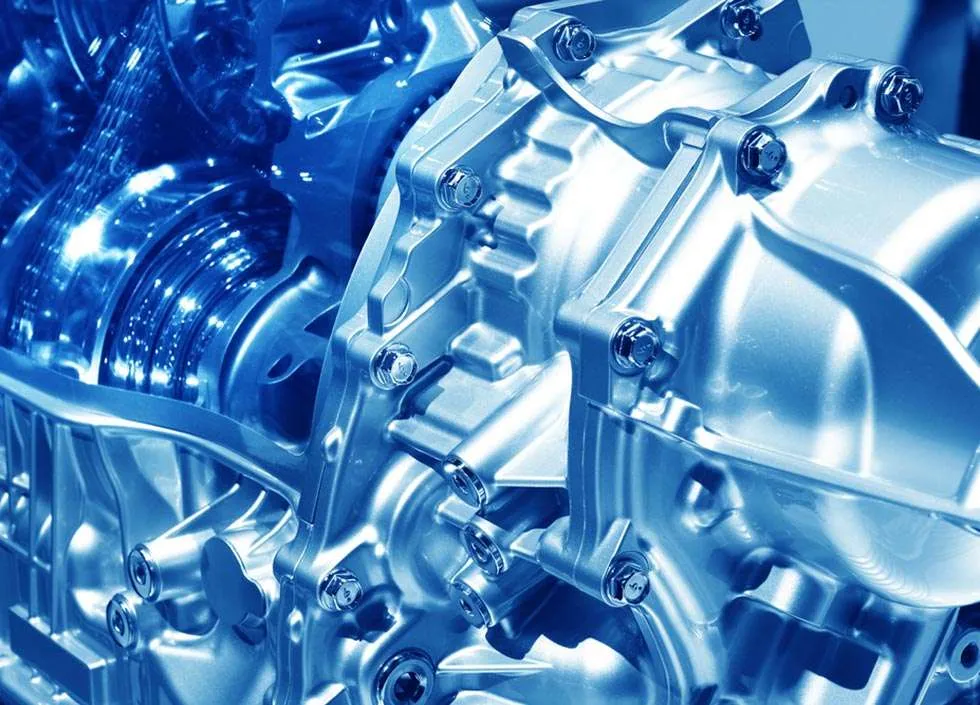

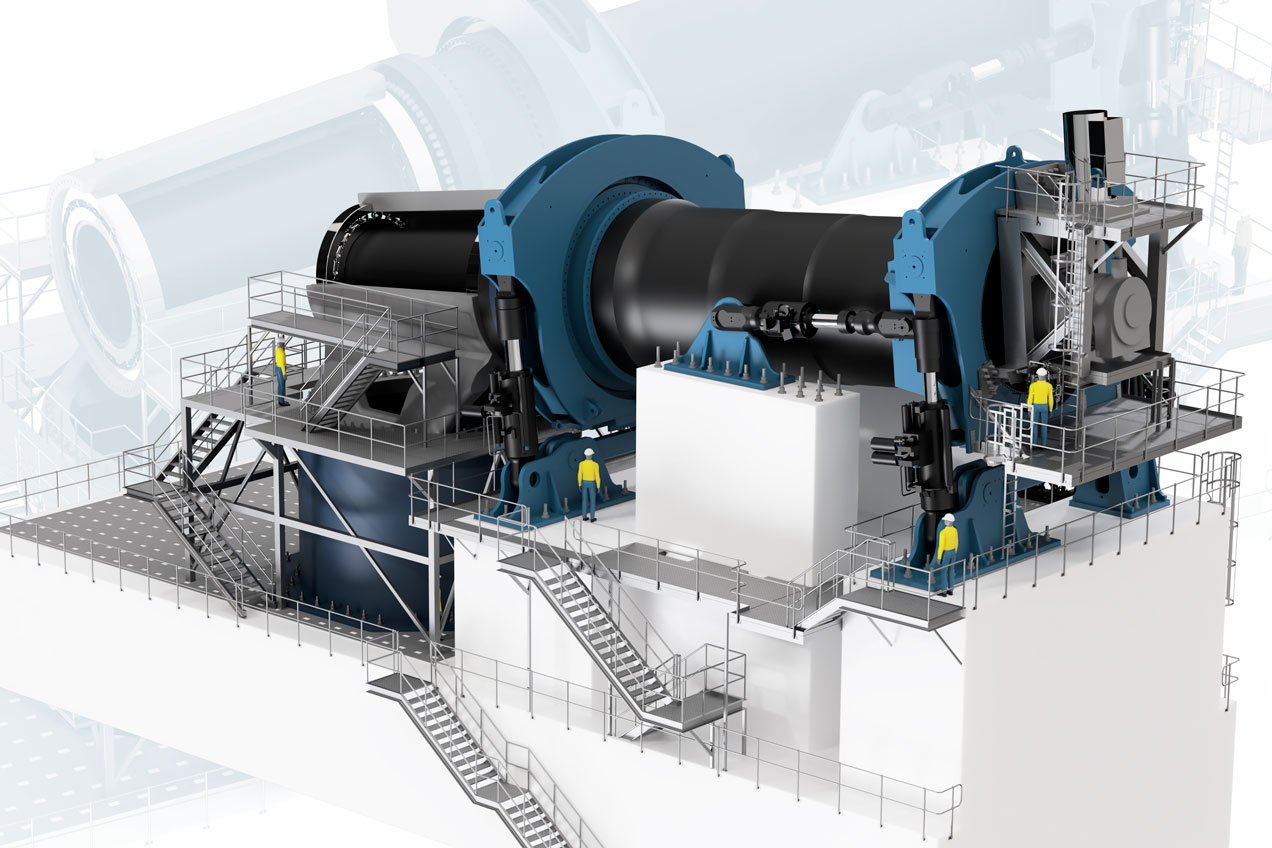

THE CHALLENGE Mechanical issues in mining crusher gearboxes can lead to high levels of oil debris wear and progress to...

Primary Crusher Gearbox Damage Prevention by Trident FQMS

THE CHALLENGE Planetary bearing faults are difficult to detect during early stages and manage through end of life using vibration...

Wind Turbine Life Extension with Trident DM4500

THE CHALLENGE Issues can arise at unexpected times within the oil’s lifetime and lead to expensive repairs and equipment failure....

Water-in-Oil Detection by Trident FQMS

THE CHALLENGE Locomotives run in remote regions and it’s hard to get consistent, timely, and accurate offline oil samples to...

Locomotive Engine Fault – Trident FQMS

THE CHALLENGE Desiccant life degrades at different rates on different equipment; replacements are based on fixed time intervals or visual...

Breather Replacement – Iso-Logic Breather

THE CHALLENGE Clocking bearings are not detectable early enough through traditional vibration-based CMS systems. THE SOLUTION Poseidon’s online wear debris sensor...

Clocking Bearing Detection by Trident DM4500

THE CHALLENGE Catastrophic gearbox failures can begin with minor component damage and accelerate undetected, even with traditional oil sampling and...

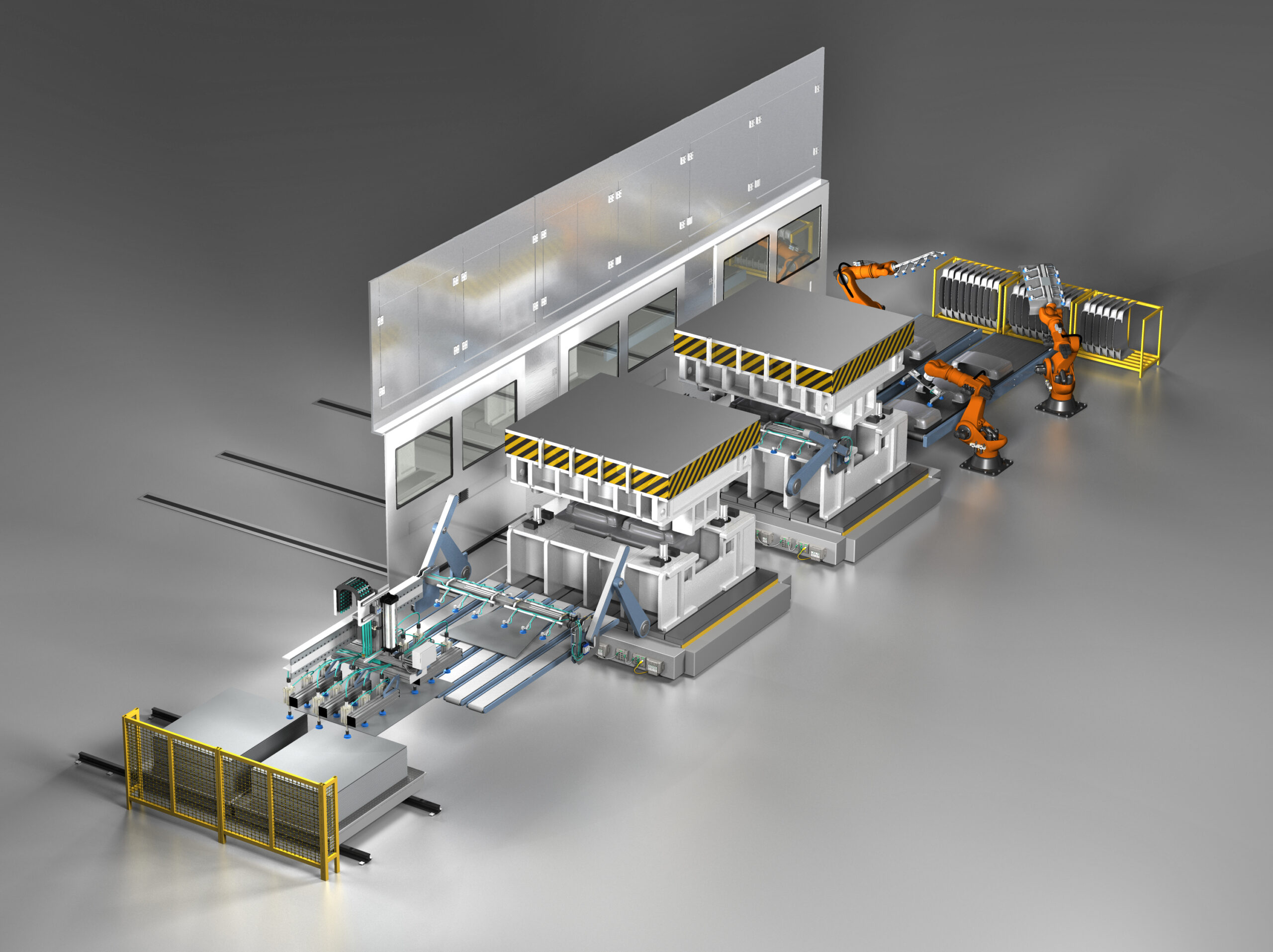

Wear Debris Detection – Metal Processing Plant

THE CHALLENGE Replacement parts have long lead times, and an immediate repair was not possible. The Trident DM4500 wear debris sensor was...

Automotive Stamping Press

THE CHALLENGE In tire manufacturing, rubber extrusion machines are critical to the operation of the entire plant and downtime is...

Wear Debris Detection – Extrusion Lube System

THE CHALLENGE A yaw motor suffering from sticking motor brakes, drivetrain lockup, or motor keyway failure will stress other yaw...

Yaw Motor Issue Detection by Yaw Motor Monitoring System

Frequently Asked Questions

Strictly implement ISO9001.

Test and verify the new product prototype through a third-party authority;

Electronic components adopt industrial-grade standard requirements, and select material suppliers;

100% of the products pass the online aging test;

Full inspection of key electronic components and materials;

Through IQC, IPQC, FQC and OQC layer by layer to control the quality.

We have regular models in stock, and usually can be delivered within two weeks after the payment. The production time for special models is 3-4 weeks.

Yateks has 5 Software copyrights,16 Patents of Invention and 8 Patents for Utility Models. In 2013,Yateks achieved the ISO9001 quality management system certification and it’s industrial endoscopes got CE&ROHS certificates.

Yateks has many global partners,such as Karl storz NDTec, Viewtech,InterTest,who put quality first.

T/T Paypal

Yateks customer service is on duty 24 hours a day, 7 days a week. Our customer service team will coordinate and resolve your issues immediately and an analysis report will be issued. If it is a confirmed quality problem, Yateks will provide a replacement machine to use within 1 month.

If it is damage from improper use by the customer, Yateks will repair the unit at the best price possible within 1 month.

For North America customer service, please contact our Yateks USA partners InterTest, Inc. immediately.

One year warranty, lifetime maintenance.

Contact us

You can leave us a message anytime if you have any questions

Yateks has a high-level R&D team led by doctors and masters who established a complete quality management system for their products.

About Us

- Our Team

- Portfolio

- FAQ

- Gallery

- News

- Contact Us

Features

- Oil Condition Monitoring

- Content Strategy

- Design & Planning

- Collaborattion

- Case Studies

- Privacy

Get in touch

- +86-755-89308753

- Info@yateks.com

- +86 152 1776 3651

- 11th Floor, Block B, Building 3, Huangge North Road, Tian An Cyber Park, Longgang District, Shenzhen, China 518172