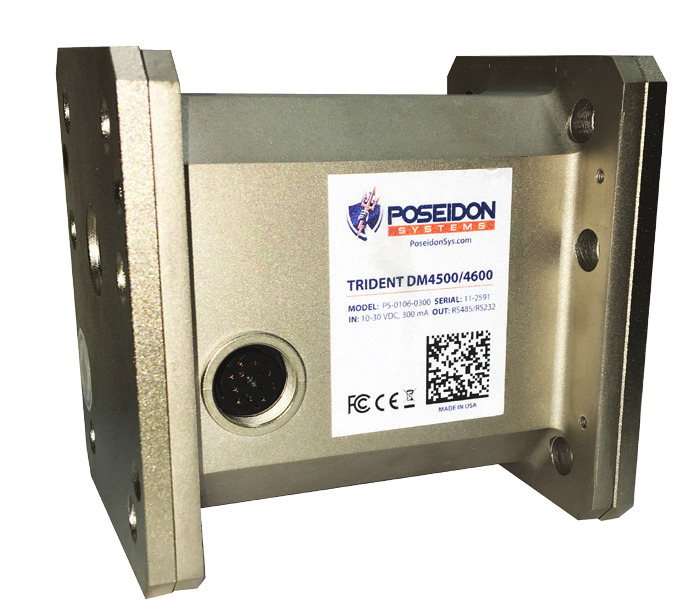

Wind Turbine Bearing Fault Detection by Trident DM4500

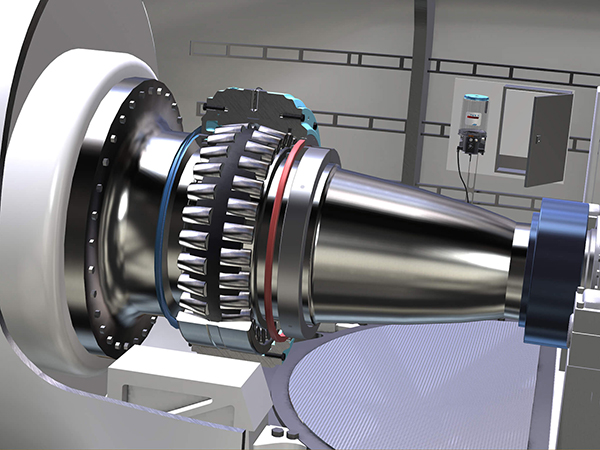

THE CHALLENGE Wind turbine planet bearings are difficult to detect early using vibration systems, but make up a majority of all gearbox failures. Operators need earlier warning of planet bearing […]