Your orders are shipped seamlessly between countries

You have the right to return your orders within 30 days.

Your payments are secure with our private security network.

Focus on oil analyzer

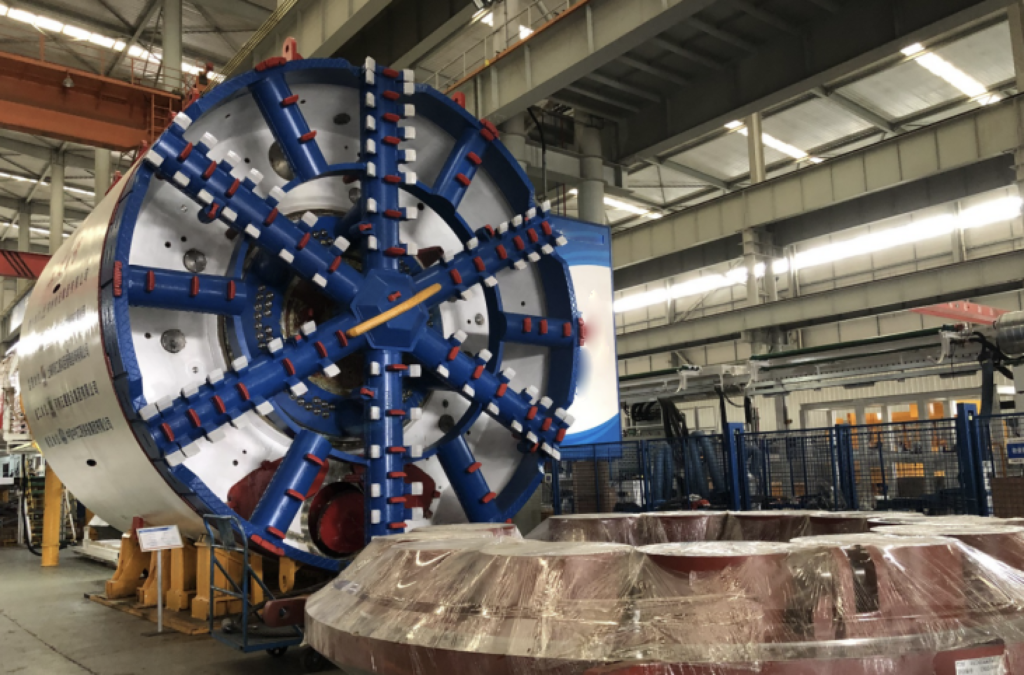

Applied in various fields

About Our Company

Over 21 years of quality and innovation

Founded in 2003, Yateks is an online oil condition monitoring solution provider integrating R&D, manufacturing and sale

Products exported to 59 countries and regions around the world, winning the wide trust of customers in different fields such as large-scale equipment condition monitoring, IIoT, transportation, aerospace and so on.

- Quality Control & Reliability

- Product Highlights & Features

- Widely applied in various fields

2000+

Team Members

innovation leads the future

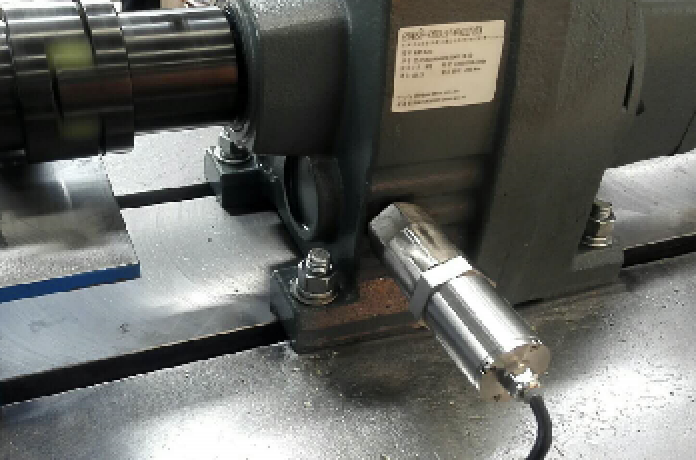

Professional oil sensor solution

Committed to repeated test and continuous improvement, polishing series products of high-precision sensors, and taking the value transfer and reliability as the core of product.

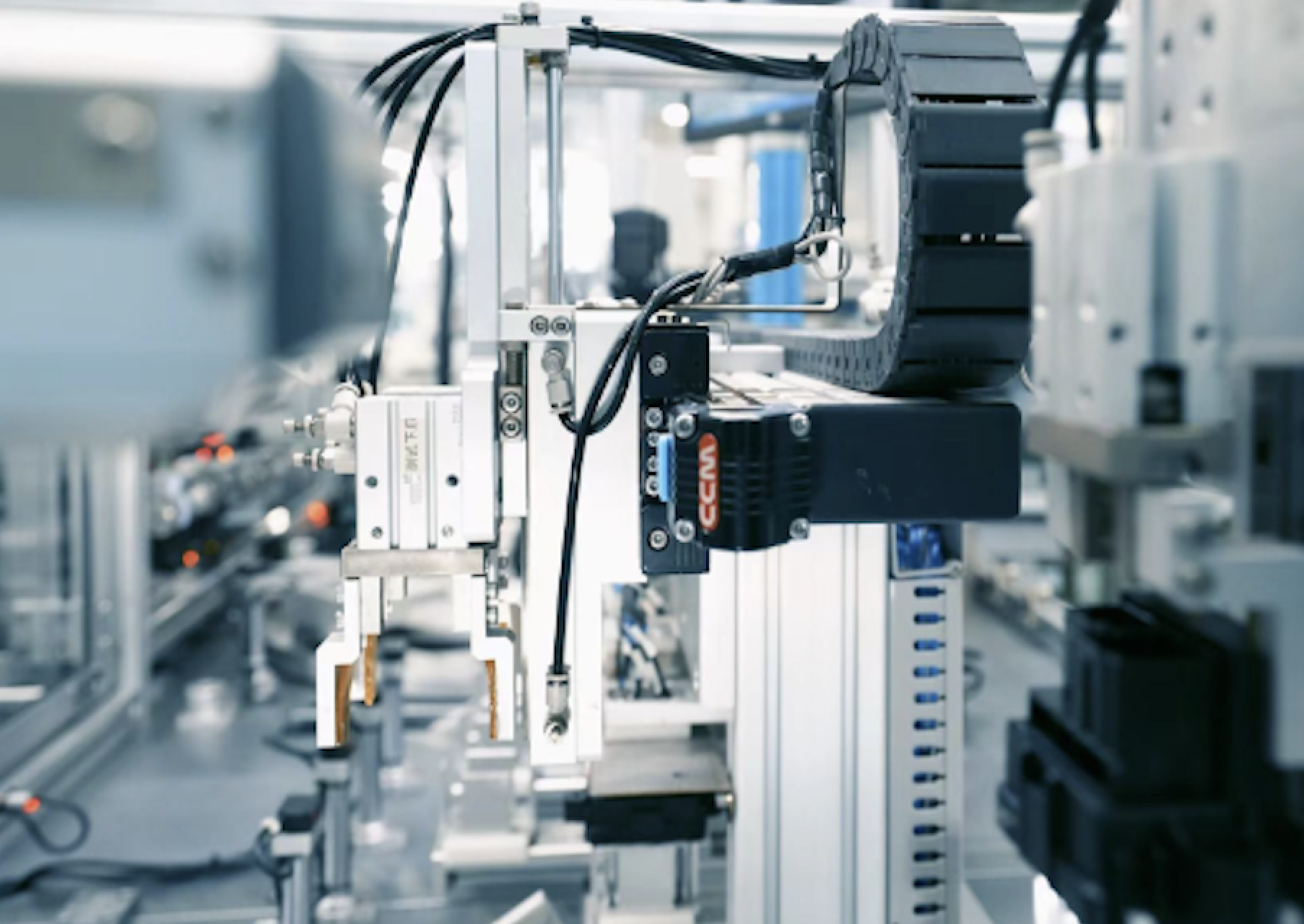

Professional

Professional equipment

Trusted

Industrial chain connection

Affordable

The price is reasonable

Expert Team

Professional team

Our Product

Improve & Enhance Our Product

TECHNOLOGY THAT IMPACTS YOUR BUSINESS

Our unique Oil sensor core technology enables continuous analyses of oil at a molecular level, enabling us to see and detect minute changes caused by contamination, wear and internal issues – long before any other monitoring technology. Our intelligent analytics make sense of this data to provide you with clear and factual statements on the real maintenance status of your equipment. Our sensors are easily installed and integrated on to existing equipment using existing oil inspection points. 24/7 global support and guidance is available from Tan Delta. Data from the sensor can be connected to existing networks and displays or one of our own dedicated displays can be used to display information. Oil is continuously analysed with status summarised as a simple TDN number and rate of change which allows accurate prediction of optimal maintenance.

SAVINGS AND BENEFITS

Dynamic Maintenance Optimisation (DMO™) allows for the extension of service intervals by up to 35%. Other benefits are; reduced servicing and maintenance, increased equipment productivity, reduced oil sampling, minimised oil waste and disposal and reduced downtime. Embracing DMO™ not only enhances the efficiency of operational processes but also contributes to significant cost savings across various aspects of equipment management.

News & Blogs

Our Latest News & Blogs

Contact us

You can leave us a message anytime if you have any questions

Yateks has a high-level R&D team led by doctors and masters who established a complete quality management system for their products.

About Us

- Our Team

- Portfolio

- FAQ

- Gallery

- News

- Contact Us

Features

- Oil Condition Monitoring

- Content Strategy

- Design & Planning

- Collaborattion

- Case Studies

- Privacy

Get in touch

- +86-755-89308753

- Info@yateks.com

- +86 152 1776 3651

- 11th Floor, Block B, Building 3, Huangge North Road, Tian An Cyber Park, Longgang District, Shenzhen, China 518172

All

All