Ships and Ports

Home – Industries-Ships and Ports

Why do we need oil analysis and online monitoring?

Key components or links:

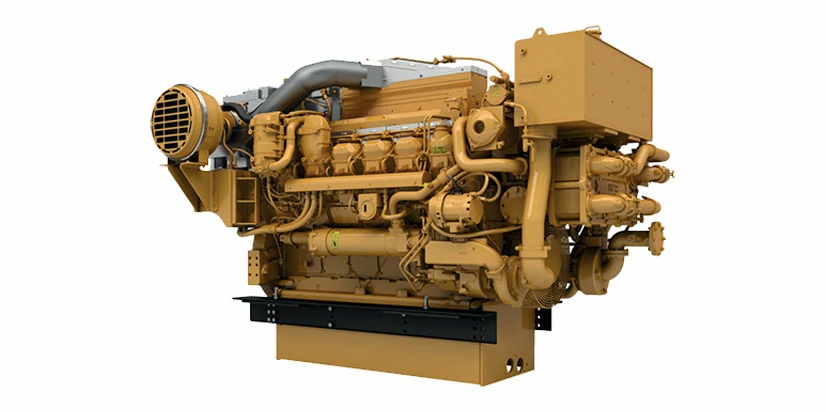

Main engine and auxiliary engine

The main engine (diesel engine) and auxiliary engine (generator, air compressor, etc.) of the ship are the power sources of the ship. The quality of lubricating oil directly affects its operating efficiency and reliability.

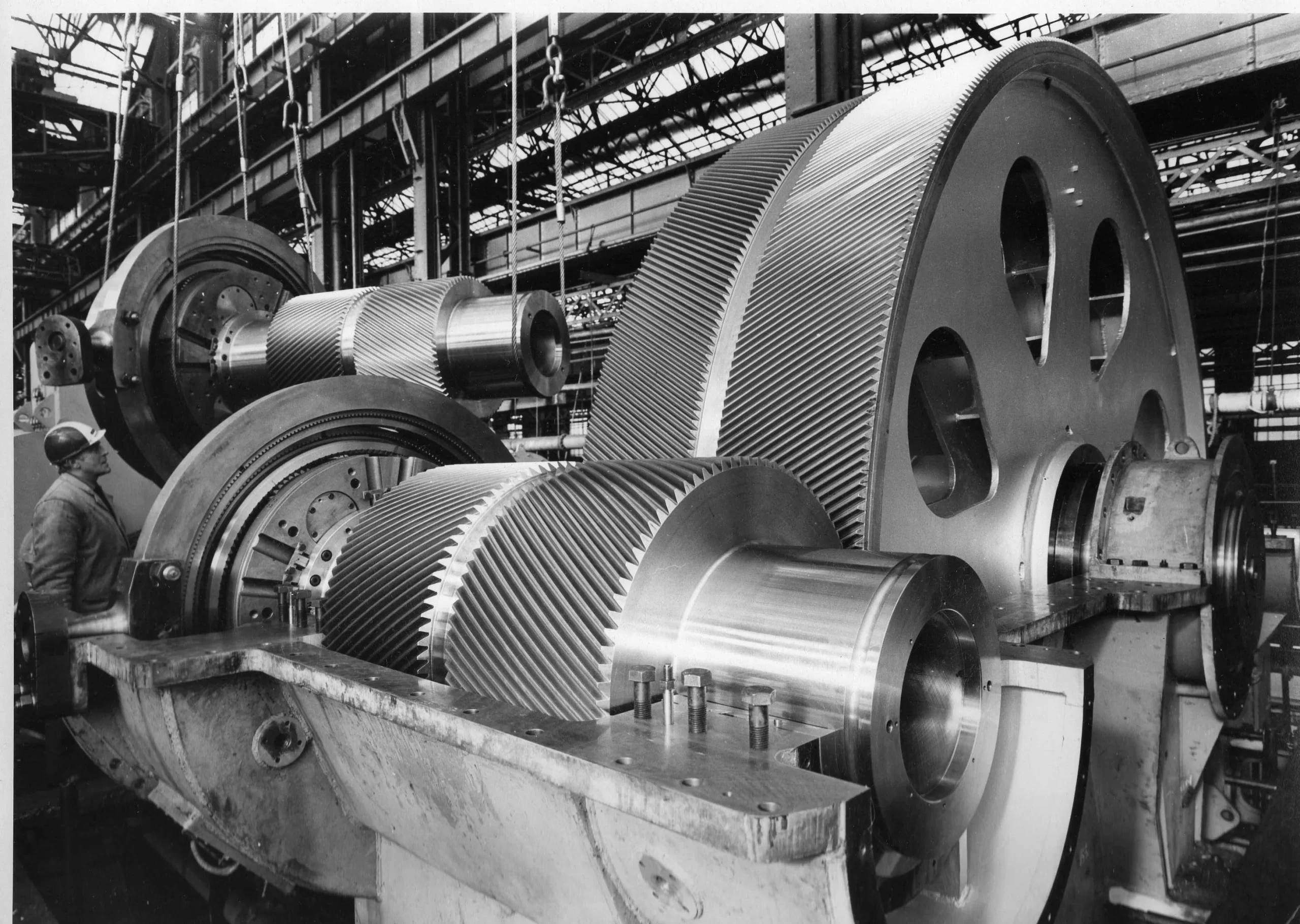

Gearbox

The propulsion system of the ship is usually equipped with a gearbox to transfer the power of the main engine to the propeller. The lubricating oil of the gearbox is under extremely high mechanical load and needs to be monitored regularly.

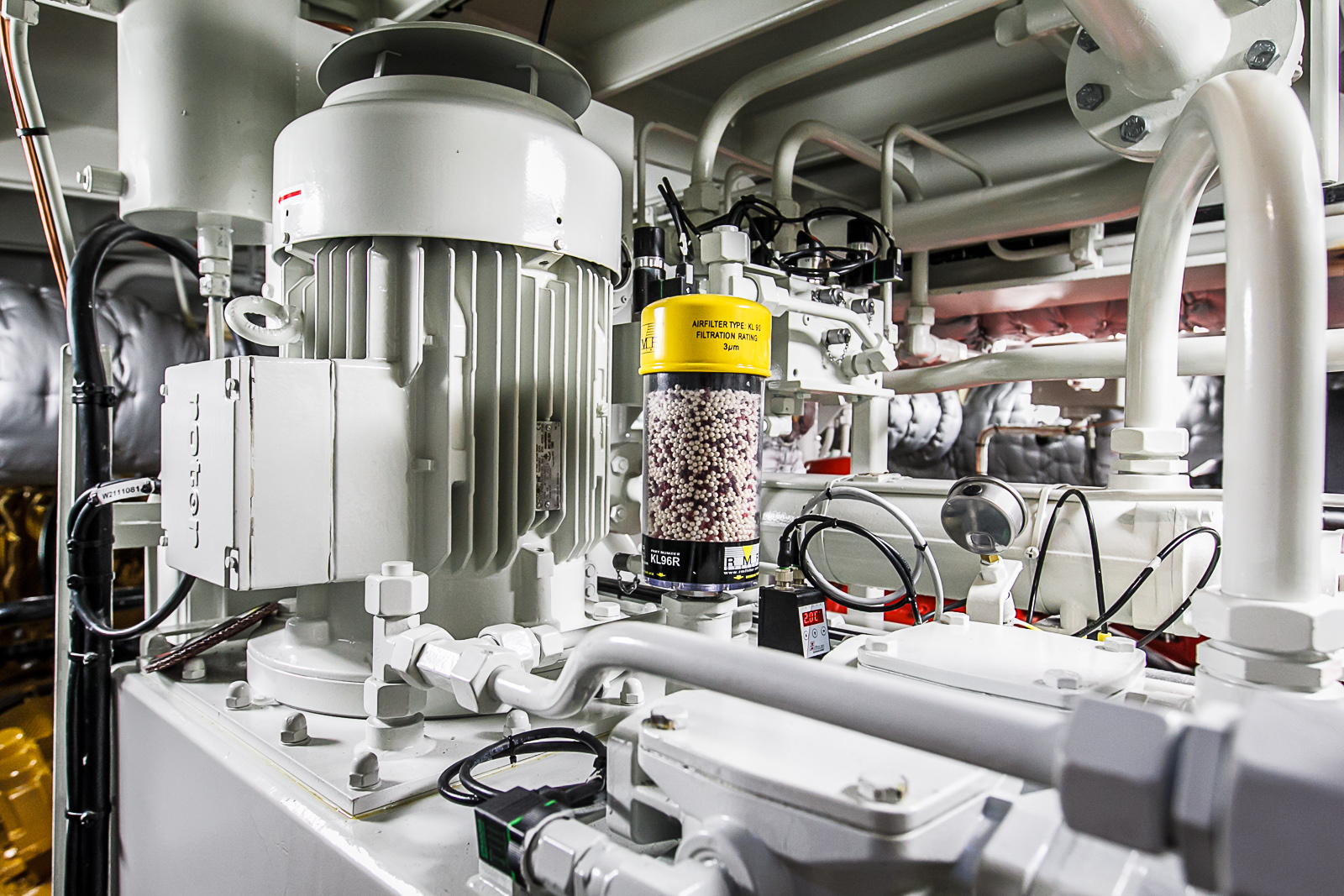

Hydraulic system

The ship’s steering gear, anchor windlass, crane and other equipment rely on the hydraulic system to work. The quality of hydraulic oil directly affects the performance and safety of these equipment.

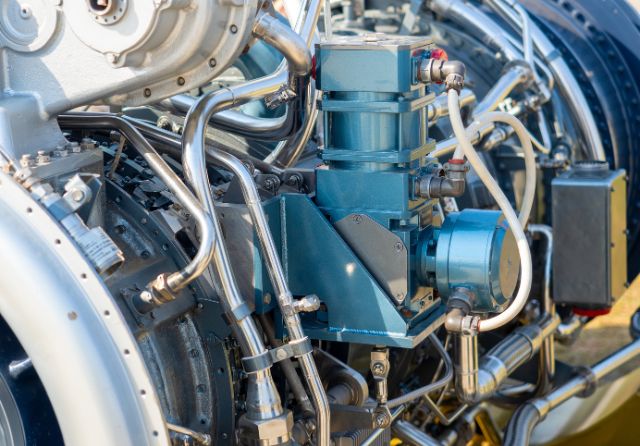

Lubrication system

All kinds of mechanical equipment of the ship need lubrication, and the quality of oil directly affects the operation of the equipment

Why is monitoring necessary?

Lubrication system

All kinds of mechanical equipment of the ship need lubrication, and the quality of oil directly affects the operation of the equipment

Ensure navigation safety

When the ship is sailing at sea, equipment failure may cause the ship to lose power or control ability, seriously affecting navigation safety. Through oil monitoring, potential problems can be discovered in advance to ensure the normal operation of the equipment.

Extend equipment life

The mechanical equipment of the ship usually operates in a harsh marine environment, and the lubricating oil is easily affected by pollutants such as seawater and salt spray. Through oil analysis, these problems can be discovered in time and the service life of the equipment can be extended.

The risks of not monitoring your oil

Monitoring solutions provided by Yateks to customers

YOL online oil monitoring system

YOL online oil monitoring system integrates a variety of advanced online oil monitoring sensors, which can monitor lubricating oil viscosity, density, temperature, dielectric constant, water activity (correlated calculation of trace water), oil metal abrasive particles, oil contamination sensors and other lubricating oil monitoring physical and chemical indicators. The system integrates data management and intelligent operation and maintenance systems.

Yateks Cloud Platform

Based on sensor technology, data acquisition, big data analysis and cloud services, the Yatai Oil and Fluid Cloud Platform deploys a distributed state monitoring system to implement intelligent monitoring and control applications of the Industrial Internet of Things, and realizes functions such as abnormal warning of online oil and fluid monitoring data, data trend management and remote equipment management, so that equipment operation and maintenance can be fully improved in terms of effectiveness, economy and safety.

Contact us

You can leave us a message anytime if you have any questions

Yateks has a high-level R&D team led by doctors and masters who established a complete quality management system for their products.

About Us

- Our Team

- Portfolio

- FAQ

- Gallery

- News

- Contact Us

Features

- Oil Condition Monitoring

- Content Strategy

- Design & Planning

- Collaborattion

- Case Studies

- Privacy

Get in touch

- +86-755-89308753

- Info@yateks.com

- +86 152 1776 3651

- 11th Floor, Block B, Building 3, Huangge North Road, Tian An Cyber Park, Longgang District, Shenzhen, China 518172